3d printing molds for casting

Instead it is most commonly used for rapid prototyping and small-batch production of custom parts. The 3D printed mold acts as a vehicle for liquid which then hardens inside during the casting process resulting in the desired structure also referred to as the casting making the terminology a bit confusing.

Lost Pla Casting From 3d Prints

Our Skilled Engineers Have Over A Decade Of Mold Design And Analysis Experience.

. Making identical parts from a 3D printer mold is simply faster and more practical if you want to churn out multiple copies. Our Skilled Engineers Have Over A Decade Of Mold Design And Analysis Experience. Much like Sylatech Siemens uses 3D printers to print prototypes which are eventually used to create molds for casting steel.

Glass Stanford bunnies with some fun textures. Part 1 Printing 3D Models for Casting. Make sure to place these molds in sand - they can break in casting and the sand will protect the bottom of the kiln.

3D Printers for Making Molds BinderJetting Technology. Ad Great Range for Kitchen Home Online. Thats because molds for casting are very often 3D printed if you have a 3D printer and know how to use it.

Conventionally these channels can only be drilled in straight lines. Place An Order Well Do The Rest. Creating a mold around our 3D printed part took us about 15 hours.

The main difference from the previously mentioned SLS technology is the use of foundry. Create the 3D Model for the Mold Create a mold in your favorite 3D modelling software. I used Autodesk Fusion 360 to substract the 3D model from the cup from a cilinder.

After 3D printing a model of a piece of jewelry the jeweler can use the model as a positive pattern. Place An Order Well Do The Rest. In 2020 we interviewed Jaco Snyman founder of award-winning practical prosthetic make-up effects and prop-making company Dreamsmith Studio and Lead Prosthetics Designer of the sci-fi series Raised by WolvesAt the time Snyman told us about his workflow to produce 3D printed molds and end-use models displayed on-screen for the first season of the show.

Reusable molds are made out of metal and other durable materials and can be reused for multiple casting cycles. 3D printers to assist the process of investment casting. 3D Printed Tools Die Casting and Injection Molding with a 3D Printer.

Design a desired 3D object in CAD Create a negative of the shape by subtracting it from a larger volume Split that negative into two halves 3D print each half Bolt them together. This results in substantial savings in cost labour and time ultimately speeding new product development. Follow the instructable for a simple method to produce soft silicone casts out of 3D printed molds.

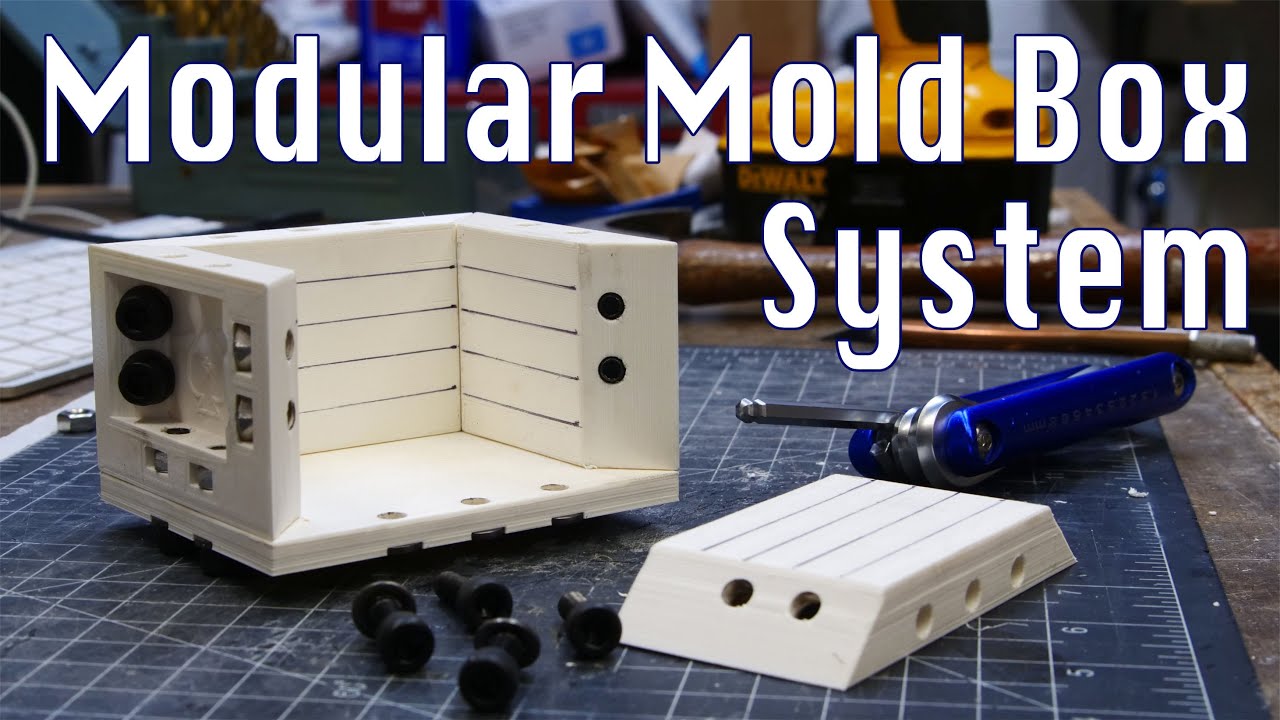

Free UK Delivery on Eligible Orders. Supplies 3D printed mold box hardware vents keys read on for more info. If youre a 3D printing person and not a glass artist yet this is something that you can do with access to a glass fusing kiln.

This technology allows you to print a sand mold with a complex geometry without any additional. At ExOne were equipped to help you quickly develop a casting mold for a one-off prototype and its ensuing iterations as well as produce 3D printed molds and cores at scale. First we create the cast Then we mix two silicone compounds usually or whatever you have and pour them into the cast - gravity takes over and replaces the air in the mold with silicone.

Creating a mold is an unconventional of using a 3D printer but it can be more practical in certain situations. Free UK Delivery on Eligible Orders. Strebel 3D printed several interlocking parts which became the mold and design of the mold is also critical.

Just keep in mind that a cheap 3D printed mold will not be as heavy-duty as one made from plaster or metal. There is more than one way to skin a cat and there are dozens of techniques for making molds for metal. There must also be a way or ways for air to escape lest it be captured in the liquid silicone.

Ad An Easier Way To Order Custom 3D Printed Parts Online. The process in 3 steps. 3D Print One-Offs Or 3D Print 1000s Of Parts.

Upload A File Order In Less Than 5 Mins. Casting into our mold took about 15 minutes. Why use 3D printing for molds.

Ad An Easier Way To Order Custom 3D Printed Parts Online. We go from a 3D CAD model to a 3D printed component to the final metallic component without having to go through the normal process of manufacturing Stephen Baker Head of RD at Siemens Rail Automation said. I cut that model in two and I added small spheres on one part and two small sperical holes on the other part so the 2 molds can be easily positioned correctly.

Ad Low Cost Expert Mold Analysis Manufacturing Services. Non-reusable molds are usually made out of sand plaster wax or by 3D printing and just as the name suggests they get destroyed in the casting process. 3D Print One-Offs Or 3D Print 1000s Of Parts.

A typical method for casting would be the following. More techno-kitsch than art but. SLS Printing of Casting Molds.

Master the print you are molding Silicone Resin and dye Mixing cups Mixing sticks Mold release spray Hot glue or cyanoacrylate glue Funnel Ex acto knife. There are many many many lessons and techniques used when developing a mold for casting. Upload A File Order In Less Than 5 Mins.

3D printing is not widely used as a moldmaking tool. The binder jetting process for 3D printing sand casting molds suits applications with a lot of 1 or 1000000. Using 3D Printing for Metal Casting.

Ad Low Cost Expert Mold Analysis Manufacturing Services. The several pieces must be tightly fit together to prevent leaks yet also provide a means of access for silicone injection. Our metal 3D printing solutions make it possible to integrate temperature control and cooling channels directly and conformally into your tools and tool inserts with DMLS technology.

Ad Great Range for Kitchen Home Online. Ceramic shells after burnout and 3D printed patterns in Clear Resin. Sand Casting With 3D Printers Sand Casting With 3D Printers With 3D printing systems available from Stratasys foundries can fabricate patterns with either Objet Polyjet technology or FDM Technology.

How To Use 3d Printing To Make Two Part Silicone Molds Matterhackers

This Is A Tutorial On How To Cast Low Temp Metal Alloys Using 3d Printed Molds The Process Involves Common Tools And S 3d Printing Diy 3d Printed Metal Prints

Casting Metal With 3d Printed Patterns

Safe Simple Affordable Cold Casting Turns 3d Prints Into Metal 3dprint Com The Voice Of 3d Printing Additive Manufacturing

Dodecahedron 3d Printed Support Shell For Silicone Mold Silicone Molds Molding 3d Printing

Parametric Two Part Mold Generator For Openscad By Jasonwebb Prints 3d Printing Diy 3d Printing Projects

Casting Metal Parts And Silicone Molds From 3d Prints 3d Printed Metal It Cast Metal

Dodecahedron Planter Mold 3d Printed Pla Sacred Geometry

Icosahedron I Mold 3d Printed Geometric Mold Cast Concrete Resin Wax Soap Concrete Molds 3d Printing Concrete Decor

Casting Aluminum Parts From 3d Prints Make

Miniature Brick Model For Creating A Silicone Mold To Cast Resin Or Cement Bricks By Naffin01

3d Printing A Mold For A Slipcasting Mold

Revolutionizing The Injection Molding Process